Our Services

From concept through to finished product, we can do it all…

Capacity & Equipment

We are enabled to manufacture components 24 hours a day, 7 days a week using a wide-range of modern machines that are calibrated to provide the best performance and output.

Production process

All of our manufacturing activities are based on defined and agreed production process so you are guaranteed the same standard of products at defined production schedules.

Quality Assurance

We have built a strong reputation for quality control which is backed-up by professional accreditation. We are ISO 9001:2015 accredited and have received numerous customer approvals.

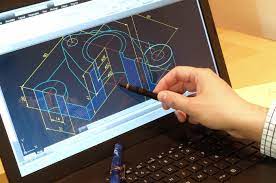

Design

At KCNC, we have a dedicated and highly skilled CAD/CAM design team who are also proficient in CNC operations. This enables us to transform designs to our cnc machines, guaranteeing perfect routing. Our Design team can take any concept and turn it into a reality. Our Design Team is fully acquainted with a number of software packages including AutoCad, Delcam, Unigraphics and more.

We have the knowledge and software to solve any problem you might have regarding the design process all handled by our professional Design team.

Services we can offer

- Mechanical Engineering Design

- Product Design

- 3D Design

- 2D Design / Technical Drawings

- 2D – 3D Conversions

Prototyping

At KCNC, we provide fast and effective prototyping for precision engineered parts, components and products for R&D, design evaluation and for ready-to-market activities for a range of high-tech industries.

We can provide a quick and efficient service to produce physical parts from conceptual models with 3D CAD drawings. Once the design is received, the prototype build process is derived and the prototype is tested and iterated multiple times with different materials to derive results.

Our Prototyping process can make use of CNC Machining, Sheet Metal Prototyping and 3D Printing.

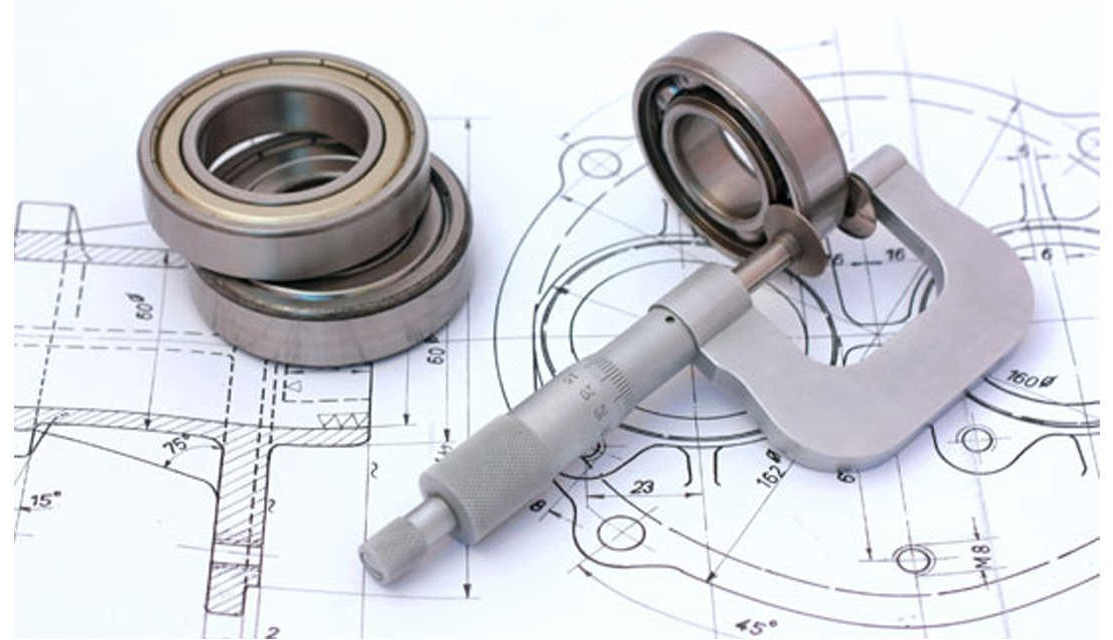

Precision Machining

KCNC can manufacture precision-engineered parts and complex components for any custom-build product or application. We are at the forefront of machining high-value components and capable of working with hard, soft and exotic metals.

Our Precision Machining expertise and capabilities enable us to,

- Quickly convert concepts into working models

- Scale production rapidly and effectively to suit customer production requirements

- Produce consistently high-quality components

- Manufacture complex and difficult to handle components through the use of jigs & fixtures

Fabrication

At KCNC, we are experienced in fabrication of mild steel, Aluminum and Stainless Steel. Our dedicated fabrication workshop within our precision manufacturing facility provides a suitable environment for welding and finishing.

We are able to offer a diverse range of specialist metal fabrication techniques including,

- Cutting

- Folding

- Punching

- Stamping

- Welding

- Assembling

Assemblies

At KCNC, we can manufacture welded and mechanical assemblies that may be small devices to complex systems with many parts sourced from national and international vendors.

We can handle all aspects of hand and mechanical assembly and any batch sizes, from prototypes to large scale production.

Some of the assembly techniques we have used in our line of work include,

- Welding

- Crimping

- Riveting

- Stud Welding

- Bushing and threaded fasteners

Finishing

At KCNC, we offer a range of surface finishing solutions including high-quality metal finishing and coating. Combining our inhouse dedicated facilities and our long-term sub-contract partners we are able to provide almost all types of metal coating and give a quality finish every time.

The finishing activites we are able to provide are,

- Electroplating involving Tin, Copper, Nickel, Silver and Manganes Phosphate coating

- Anodizing

- Polishing

- Powder Coating

- Vibro/De-burring

Contract Manufacturing

Leveraging our strengths in our highly skilled resources, our extensive industry expertise and the latest machinery we can provide an efficient manufacturing process that can adhere to your internal manufacturing processes such as KANBAN or Just-In-Time, Lean Manufacturing.

The full scope of our Contract Manufacturing activities can include,

- Precision Machining

- Fabrication

- Finishing

- Assembly

Reverse Engineering

Our Reverse Engineering Service delivers a perfect end-to-end process from designing, testing, design analysis, optimization, redesigning and manufacturing.

Our reverse engineering service can be accompanied with 3D printing services to reduce the turn-around time of the process.

Why Choose US

Quick Turn-Around

We are committed to minimize the time from enquiry to delivery by combining the latest technologies and expert resources to provide you with quality products in the shortest time possible.

A One-Stop Shop

We are equipped to provide the full spectrum of services from modelling components to component finishing so your product will be delivered without having to deal with multiple vendors.

Free Consultation

You can contact us any time to get a no-obligation consultation to provide you with access to cost-effective products and services or for reverse engineering your existing components.

Find out about our services

We manufacture high-quality, competitively priced components and assemblies. Share your requirement and any drawings you may have.