Our Capabilities

From concept through to finished product, we can do it all…

Capacity & Equipment

We are enabled to manufacture components 24 hours a day, 7 days a week using a wide-range of modern machines that are calibrated to provide the best performance and output.

Production process

All of our manufacturing activities are based on defined and agreed production process so you are guaranteed the same standard of products at defined production schedules.

Quality Assurance

We have built a strong reputation for quality control which is backed-up by professional accreditation. We are ISO 9001:2015 accredited and have received numerous customer approvals.

Industry Sectors

Aerospace

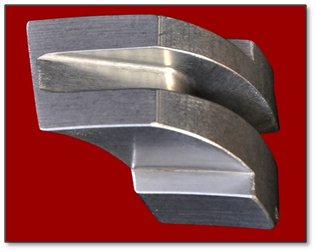

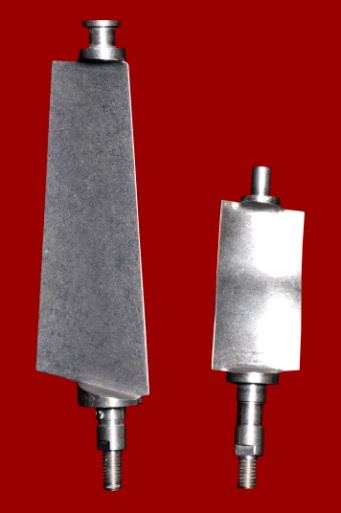

KCNC manufactures high-performance aerospace grade components. Our technology, knowledge, and experience enable us to produce highly complex components made of soft and hard metals for the aerospace industry, to an accuracy of ±0.02 mm.

Defence

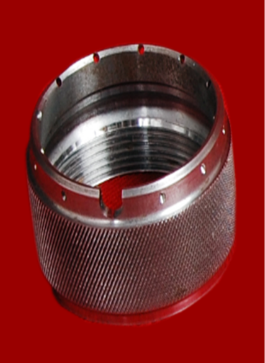

KCNC prides itself for providing components for programmes that are vital to our national security. We have experience in structural components for land and air-based systems including artillery, ballistic protection, surveillance and military weapon systems.

Power Generation

KCNC offers competitive solutions for turbine parts to address reliability, life exrtension and capacity demands by providing retrofit and turbine part solutions for steam and gas turbines. We specialize in Rotor and Stator blades, Vanees and Diaphragms.

Industry Experience

Aerospace

- Design & manufacture of Jigs and Fixtures

- Aero engine Titanium and Inconel Blades

- Structural components for Boeing, Su 30 Sukhoi aircraft

- Components for Hawk AJT

- Door components for Airbus A320

Defence

- Turret Positioning components for T-72 Battle Tank

- Back Plate Assembly for AK-630M Naval Gun

- Ashani 0.32” Caliber Pistol body and firing pins

- Multi Grade Launcher assembly

- Night vision equipment housing and fuses

Power Generation

- Stator and Rotor steam turbine blades up to 500 MW

- Nozzles, Nozzle Plate, Diaphragm assembly, Labyrinth

- Re-engineering of turbine up to 25 MW

- High Pressure Various control valve assemblies for steam turbine

Quality Control

KCNC has built a strong reputation for quality control since our founding. This hard-won reputation is backed-up by professional accreditation. We are ISO9001:2015 accredited and this, alongside numerous customer approvals, assures you that we deliver quality components and services.

We use CMM facilities, CNC vision system technology and a host of high-specification equipment within our inspection department to provide first-off, intermediate and final inspection of components. This inspection is “tailored” to the complexity/accuracy of the individual component and the quality requirements of the client.

From incoming enquiry to final despatch, all products are tracked, controlled and documented using our robust Production Control Process.

A Control Plan/Operation Process is produced as standard for every component we manufacture. Each operation is progressed as the previous one is completed, ensuring all operations are completed fully and in the correct order.

Infrastructure & Machinery

KCNC has set up a 4,000 sq. mtr. workshop at KIADB Aerospace Park in

Devanahalli, Bangalore with further scope for expansion within the 10,000 sq. mtr. plot.

The workshop is equipped with adequate power, back-up power and climate control facilties for sensitive equipment. A dedicated design center with the latest software tools from AutoCAD, Solidworks, DELCAM and Unigraphics supports the production process.

The workshop includes 14 3-axis and 4-axis machining centers from DMG, HASS.BFW, AMS and LINZ. Wire cut EDM, Spark erosion CNC machines and a Carl Zeiss 3D co-ordinate measuring machine.

Additional 4-axis machines, 5-axis machine, Turn-Mill Centre are under procurement.

Best in class CNC Machinery

KCNC is equipped with the most up to date technology and state of the art machinery in precision engineering. This ensures we uphold our quality standards of precision metal machining.

We pride ourselves on taking on difficult jobs that others may have tried and failed at. No matter how complex the requirement, our combination of expert team and best in class machinery can confidently address the requirement.

Production Machinery

- 3-axis Vertical Machining Center

- 4-axis Vertical Machining Center

- Universal Machining Center

- Turning Center

- Precision Hydraulic Surface Grinding Machine

- Wire EDM

- Spark Erosion

- Vibro Tumbling Machine

Inspection Equipment

- 3D Co-ordinate Measuring Machine

- Portable Surface Roughness Tester

- Internal Micrometer

- Dial Test Indicator

- Digital Height Gauge

- Feeler Gauge (26 leaves)

Get A Free Consultation & Estimate

We manufacture high-quality, competitively priced components and assemblies. Share your requirement and any drawings you may have.